A micro manufacture run by a single craftsman.

The road was long but pleasant. The need came from nowhere, but it was strong. It started with practice without knowledge. The first cuts in the workshop of a leatherworker with 40 years of experience. A few conversations with a shoemaker with 30 years of experience. Later, supplementing knowledge and building my own workshop. Trials, mistakes, lots of mistakes, first successful projects, hundreds of poor implementations.

At the end of the journey I knew what I wanted to create. I wanted to keep a balance between traditional techniques and the possibilities of production on a scale. I wanted to get the most out of the manual processes while still being able to make repeatable products.

I design by hand - paper, pencil, squares and compasses, and at the end of the process I transfer everything to the computer and create repeatable dies. I cut, glue, sew by hand at the design level, and then I adapt the leatherworking machine, cutting press and other equipment to replicate my handcraft. I built many parts for my sewing machine to replicate my hand sewing. I rebuilt and expanded the bench grinder to be able to process and polish edges using techniques used by shoemakers and jewelers. I designed a press with a pressure of several tons so that during the cutting process there would be no material rejection. I run a studio and workshop, as well as a factory in one place. I have the entire process under control, which is difficult on one hand, but really satisfying on the other.

Tools, threads and applications

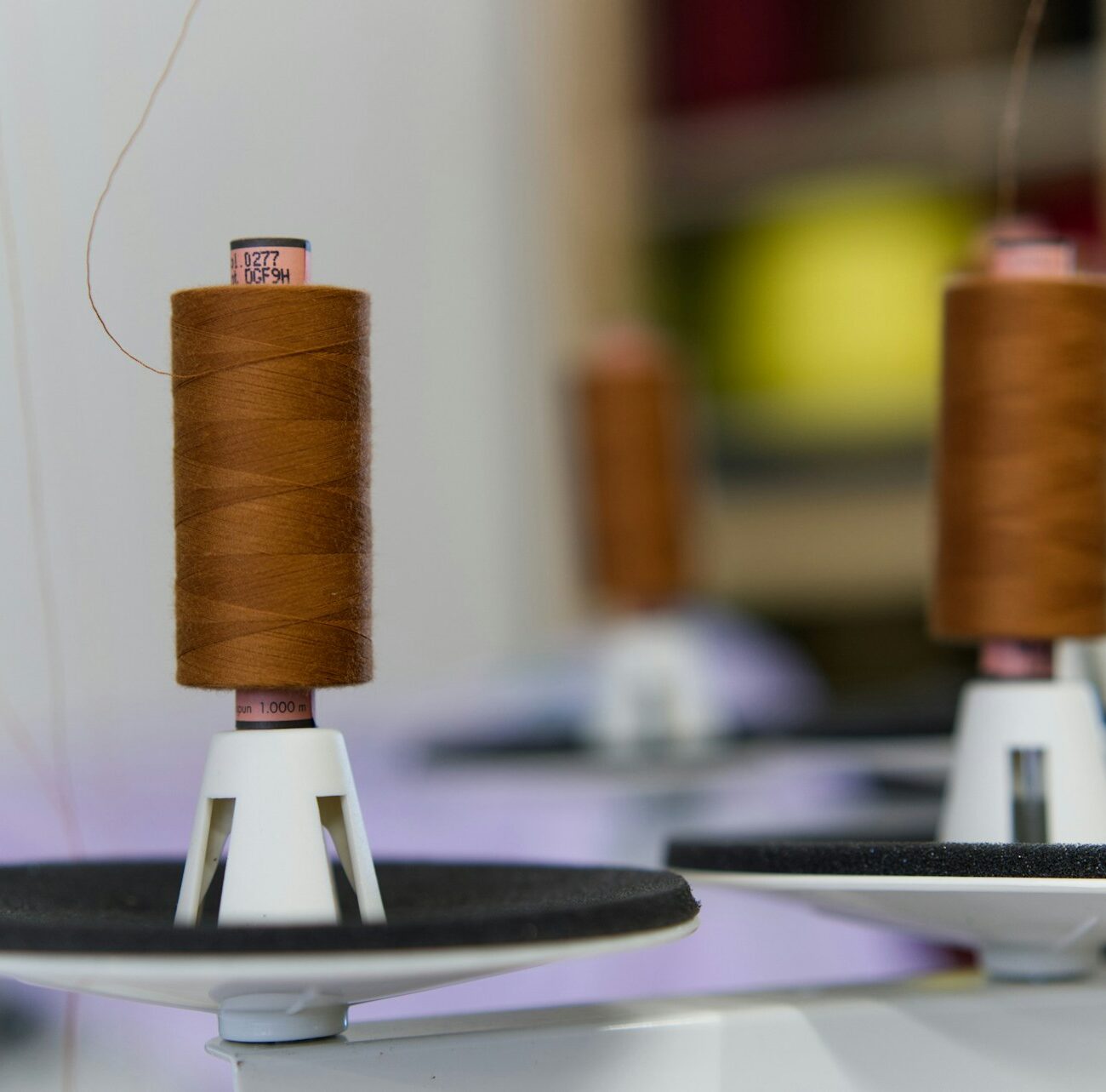

Threads

When I use a leatherworking machine for sewing, all threads come from a factory established in 1897 in Łódź, the center of the textile industry in Central Europe. When I sew by hand, I use Italian, waxed, braided thread produced since 1986, and blunt needles, created especially for saddle stitch sewing.

Glue

When creating the products, I only use water-based glue from an Italian factory established in 1967.

Hand tools

I cut and finish edges with Japanese knifes and tools, handcrafted by craftsmen with decades of experience

Machines

When I sew and thin leather, I use traditional, mechanical devices from a company with 60 years of experience.

Applications

For finishing and skin care, I use mainly water-based products. I try not to interfere too much with the skin structure, which is why I choose mainly natural dyes, animal fats, and vegetable oils.